|

|

|

|

|

Innards of A Chocolate Factory | *

*

*

*

*

* *

*

*

*

*

* *

*

*

*

*

*

To

choose the colour of your factory, hover over the asterisks... |

Task I Task I

Cleaning

The Mixer

A. Get a parts cart or

flatbed.

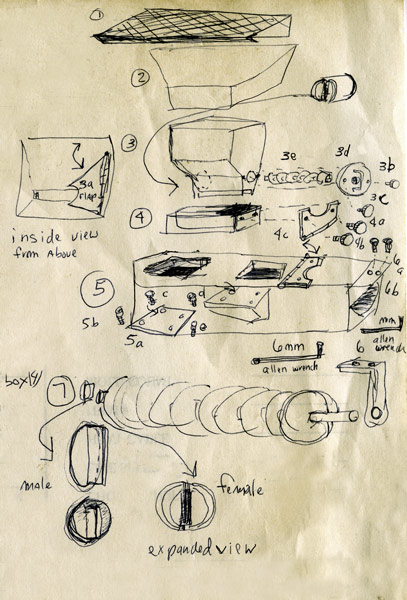

B. Lift off the screen (1),

lay it back out of harm’s way.

C. Lift off bin (2),

lay back out of the way.

D. Scoop out contents into a good carton.

E. When the auger is uncovered,

vacuum the rest,

lifting the flap (3a) to get everything

F. Unscrew hand screws (3b and 3c)

G. Remove cover (3d) by its handle

H. Wipe it off.

I. Remove auger.

J. Lay everything on a cooler duct.

K. Unscrew hand screws (4a and 4b)

L. Swing down flap (4c)

M. Lift off small bin (3), separating it from the

box (4).

N. If small bin has chocolate on its bottom,

carry downstairs and put on the parts truck or

flatbed.

O. Remove box (4) and wipe clean if possible.

If not put on truck also.

SHUTTING DOWN THE SYSTEMS

FOR DUMMIES

(an easy to follow guide

for the rest of us)

These procedures can be used to meet any

of 4 goals:

#1. A shutdown due to malfunctions of

varying degrees.

#1 A. Emergency

#1 B. Non emergency

#2. A system that is ready to go for the

next run either hours or days in

the future. This is the usual, most

normal way of shutting down.

#3. A partially empty system ready for

an ingredient change.

#4. A entirely empty system ready for

maintenance work or a change of

product type.

******************************************************************************

┌───┐

│1 A │

└───┘

Shutting Down As Quickly as

Possible Upon Hearing a Piece of

Equipment

Make Self destruction Sounds, or

Smoke or Flame or Flood Appears.

Objective: You want to avoid damage to

equipment, or hazardous

conditions.

A. Push in the red emergency slap button

on the door of the large yellow

cabinets housing the PLC.

B. Select "System Stop" on the system

that needs to be shut down.

C. If a part of the process is going

haywire & nothing is actually on

the verge of exploding or otherwise

doing damage to the system it is

probably safe to simply shut off the MCC

breakers &/or the local

breakers for the problem area. The

situation can then be assessed &

you can decide if a system shutdown is

needed. If so, follow the

steps under #1 B.

*****************************************************************************

┌───┐

│1 B │ Shutting Down As Quickly As

Possible Due To:

└───┘

a. Maintenance needing to repair

something as soon as possible.

b. You have run out of space in all

Final Tanks.

c. You have run out of an ingredient

such as sugar, whey, oil,

etc.

d. Lack of time for some reason.

Objective: You only want to finish the

batches already begun & to

empty the 2 sets of scales.

A. Select "None" Fat Tank (if a batch of

fat is already beginning to

come in, wait until it is all in).

B. Hit "Shutdown Powder" (if it is

already bringing in the first

ingredient, wait until it starts

bringing in the second ingredient).

C. When the kneader is empty & the weigh

scale is empty, "System Stop"

may be hit.

D. If there is still a batch up in the

weigh scale you will have to turn

back on the fat tank that was being used

for one more batch. Go back

to "Cycle Parameters" & select the tank.

Wait for the fat to come

in, then go back & select "None" fat

tank again. On the other hand,

if maintenance is in an extreme hurry to

begin the repair, this step

may be

deleted and whoever starts up will need

to make a manual batch in

the kneader and also run the grinding

area manually until that dry

batch can be dropped.

E. If there is no rush you can wait

until the high level sensor is on at

the surge hopper, & the screw conveyor

to the mill shuts off, before

hitting "System Stop".

F. If there is plenty of time & you want

the system full, the high level

sensor of the pre mixer should be on. If

the last weigh scale batch

has dropped into the mixer & the high

level sensor is not on, another

weigh scale batch can be run. Don't

forget to hit "Shutdown Powder"

after the first ingredient is brought

in. If an ingredient has run

out, of course, this cannot be done.

*****************************************************************************

┌──┐

│2 │ Having The System Down & Full By A

Certain Time

└──┘

Objective: You want to run as many

batches as possible in the

available time, you want the 2 scales

empty & you want the surge

hopper & the pre mixer full. Again, this

is the most normal usual

way of shutting down.

A. Using the End of Run Summary

determine average batch time for the

past

couple hours on each system. Figure out

the # of your last weigh

scale batch so you'll know when to hit

"Shutdown Powder". Figure out

your last kneader batch so you'll know

when to select "None" Fat Tank.

1. End of Run Summary is found under the

"Recipe Download" pull down

menu.

2. Choose your System, go to the last

batch using the black arrow

boxes.

3. Looking at the "Date/Time" box on the

right, note the time. This

is the time that the kneader discharge

valve opened to begin

pumping out the finished batch & this is

when the system counts a

batch at the kneader.

4. Go back a few batches noting the

times each one finished & figure

out the time between: these are your

batch times(that is, the

length of a batch). Take the hours you

have to run yet & divide

by this average batch time to get the

number that can probably be

run.

5. To ensure that you are on track time

wise mark down your projected

batch times. This will also give you the

# of the last 4 batches

of cocoa. (for example: if you figure

out batch time is about 40

min. then if batch #34 begins pumping

out at 7:15pm + 40

min.batch time = batch #35 begins

pumping out at 7:55pm + 40 min.

= batch #36 begins pumping out at 8:35pm

+ 40 min.= #37 begins

pumping out at 9:15pm, etcetera.)

6. The system counts a batch at the

weigh scale when the slide gate

of the weigh scale closes after dropping

the batch into the pre

mixer. (System I pre mixer is called

Scott Mixer. The one on

System II is called BE 2000.

7. Normally it takes 2 weigh scale

batches to make one batch at the

kneader so it is safe to calculate

needing twice as many batches

at the weigh scale as at the kneader.

8. So if you know the last batch out of

the kneader will be, for

example, #32, that means you can

probably let the weigh scale

bring in 64 batches.

C. If the system is going to be down for

more than 8 hours the lower bin

of the cocoa bin should be drained.

1. Close the manual slide gate above it

& let the lower bin run

empty.

2. The bin holds about 436 lbs. which

could make about 4 weigh scale

batches but this will depend on the

recipe(s) being run.

3. Remember to close off the air supply

to the air sweeps before

opening the door of the lower bin.

4. Place a large white pan under the

door before opening. Use a

large scoop & a paddle to push the cocoa

down to the airlock. Do

not let the paddle get near the moving

airlock: turn off the

local breaker for the airlock if you

need to work near the

airlock.

5. Often the cocoa will not move through

the airlock fast enough &

you will need to scoop it out & dump it

into the air intake of the

BD pipe. (Remove the air filter cover &

the air filter first.

Use Caution! The blower will immediately

suck any objects smaller

than the pipe's opening into the pipe,

including & not limited to

the gloves off your hands. Use Caution!)

*****************************************************************************

┌──┐

│3 │ Having the system ready for an

ingredient change

└──┘

Objective: Last batches should be out of

the kneader & the weigh

scale, the Pre mixer will be empty, and

the surge hopper will be

empty or low.

System I only for dry ingredient change:

A. Determine the number of the last

kneader batch. Determine the

number of the last weigh scale batch.

Monitor a couple weigh scale

batches being dropped to see at what

point the high level sensor of

the surge hopper turns on. Make sure the

Pre Mixer is regularly

showing its high level sensor.

B. See above directions for emptying

lower cocoa bin. If you are

changing the ingredients in the bins

before your normal last weigh scale

batch if only the Pre mixer

needs to be empty; 8 if the surge hopper

must also be empty.

C. Hit "Shutdown Powder" 3 batches

before the normal last weigh scale

batch. The lower cocoa bin should have

been empty at that point.

|

|

| |

|

| | |

| | |

|

|